|

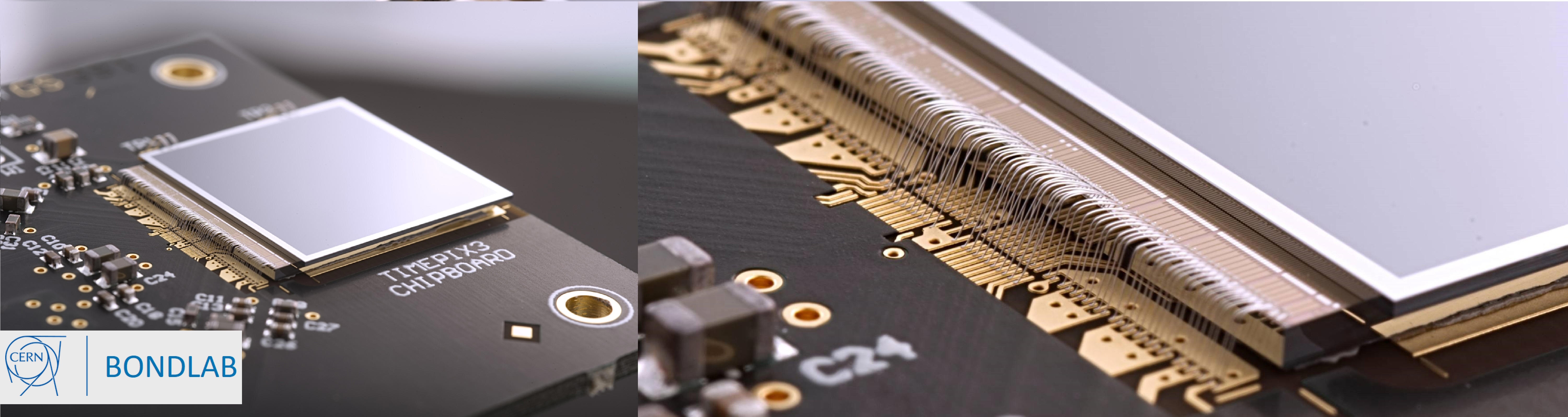

What is wirebonding?

Wirebonding is an electrical interconnect technology developed by

microelectronics industry and today used excessively in (solid state) detector

construction. It allows to interconnect electronic chips, printed circuit

boards, pitch adapters and solid state sensors.

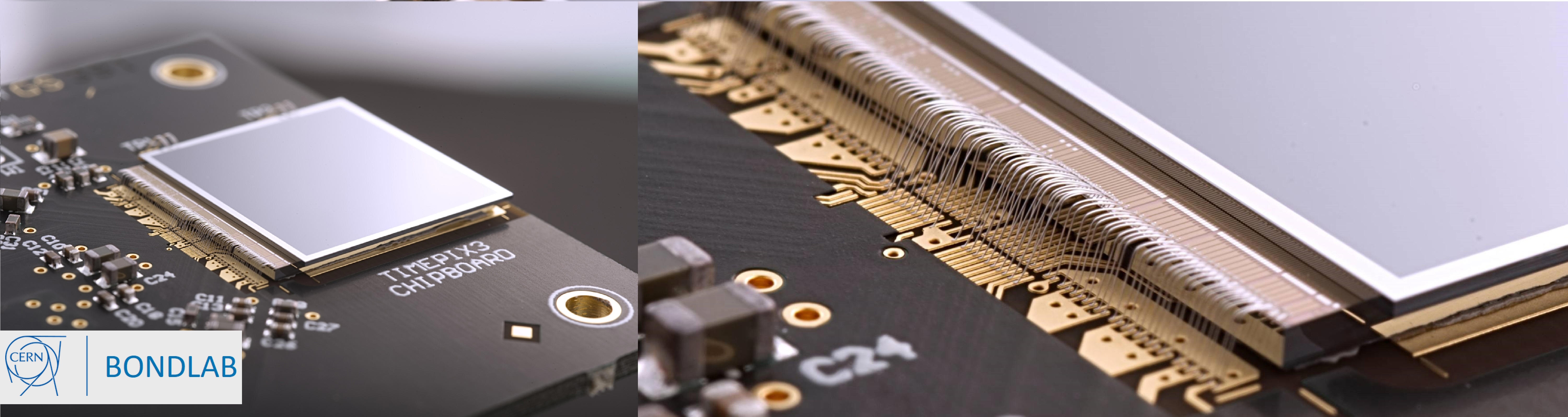

The Wirebonding technique is

a solid phase welding process which uses thin wire and a combination of heat,

pressure and/or ultrasonic energy.

What

types of wirebonding processes exist?

Wirebonding process begins

by firmly attaching the backside of a chip to a chip carrier using either an

organic conductive adhesive or a solder

(Die

Attach).

The wires then are welded

using a special bonding tool (capillary or wedge).

Depending on bonding agent,

we can identify three major wirebonding processes:

|

Wirebonding processes

|

Pressure

|

Temperature

|

Ultrasonic energy

|

Wire

|

Pad

|

|

Thermocompression

|

High

|

300-500 oC

|

No

|

Au,

|

Al, Au

|

|

Ultrasonic

|

Low

|

25 oC

|

Yes

|

Au, Al

|

Al, Au

|

|

Thermosonic

|

Low

|

100-150 oC

|

Yes

|

Au

|

Al, Au

|

Alternatives

to wire bonding

Tape Automated Bonding (TAB)

uses thin Cu beams instead of wires. The beams are held in place by thin polymer

tapes (usually Polyimide) and form a microcable.

The STAR experiment (BNL)

and ALICE are employing a form of TAB technology.

Flip chip bonding, often also referred to as bump bonding

currently provides the highest connection density. Invented in the mid 1960s,

the technology uses bumps (conductive polymers, Indium or solder bumps,

microballs) instead of wired to bond the flipped chip to a substrate. In HEP the

flip chip technology is so far exclusively used in the construction of Si pixel

detectors, where a Si sensor, segmented as area array of individual diodes need

to be connected to the readout chip, correspondingly segmented.

The

Bondlab is performing exclusively Ultrasonic Wedge Bonding with Aluminum wire.

|