|

Recommendations for the design of hybrids

(from the bonder's perspective)

: - Design and layout considerations -

The bond surface

The

main criteria from the perspective of bonding:

The material and its

structure are compatible with the available method of bonding. In the case of

the Bondlab, the method used is Aluminium Wedge Bonding.

The bond surface should

be clean and free from all contaminants. Contamination sources are many and

varied, from the obvious such as a fingerprint to the more subtle and less

obvious.

The bond

surface should be flat and of a consistent thickness and quality with no surface

damage or irregularities.

The bond surface metal should be of a comparable

hardness to the bond wire used.

The bond surface metal is bondable. This can be

tested using the bond pull test.

Shape and Size of Bond Pads

This aspect of bonding is very much dependant upon the method of bonding that is

foreseen, Aluminium wedge bonds need a more rectangular bond pad form whereas

gold ball bonds favour a more square form pad.

It is not to say a wedge bond

cannot be bonded on a square pad, but one must keep in mind the pad size with

respect to the size and form of the bondfoot in three dimensions.

From a

Hybrid point of view it is prudent to make the bond pad as large as is

realistically possible. This allows a greater flexibility with respect to

placement of the bond, placement of the die and fiducial to bond pad repeatable

registration.

Pitch and Placement of Bond Pads

A

bond pitch of 60µm is possible with 25µm wire, but the loop will be limited in

height due to the nature of the Double Side Relief Tool which is necessary for

fine pitch Aluminum wedge bonding.

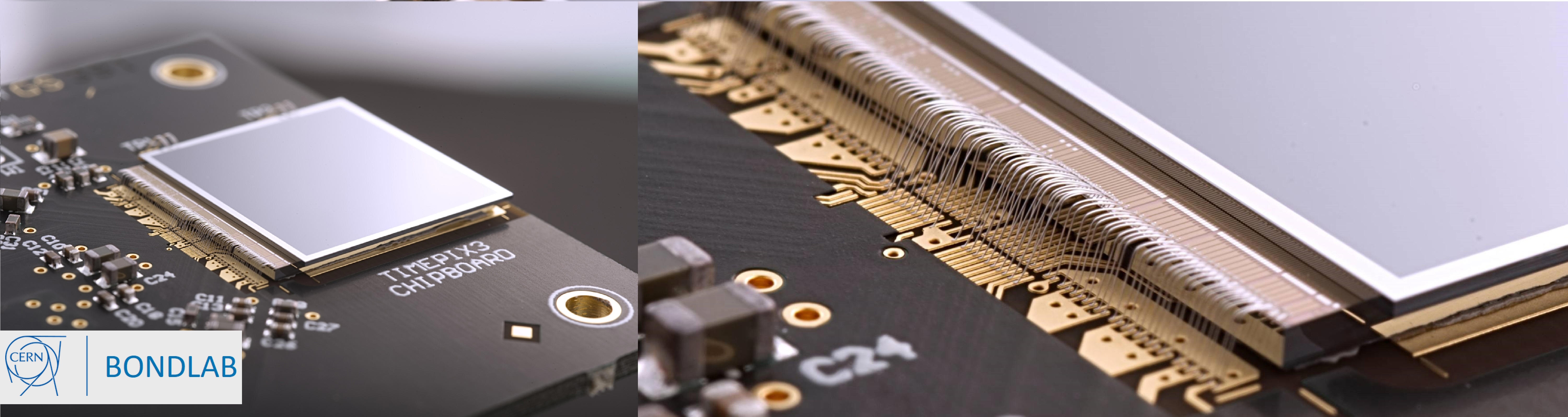

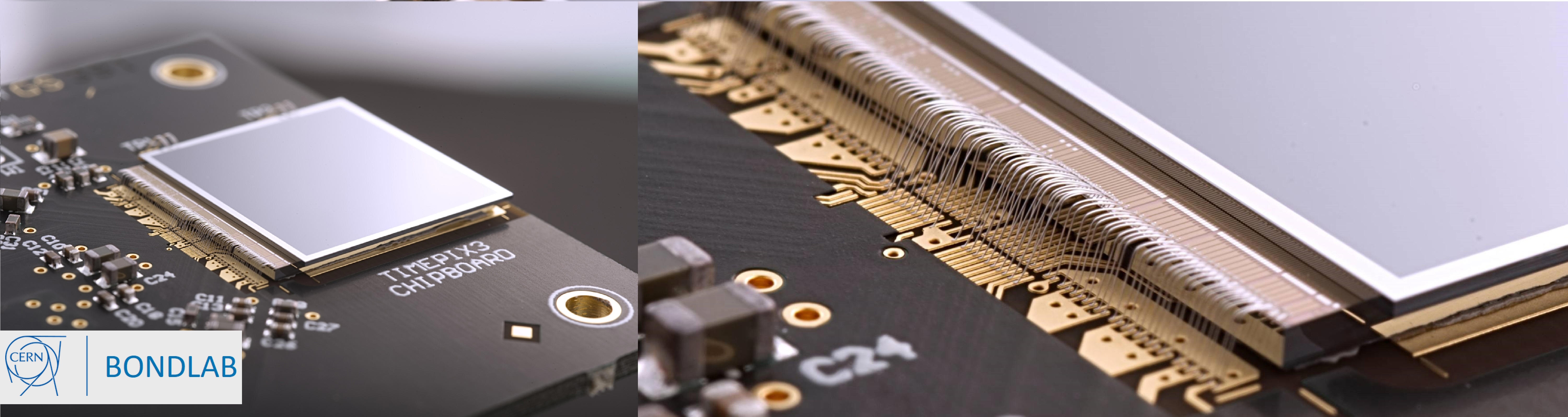

Double side relief tool ... another view

The

thermal stress effects on the first bond heel by the loop should also be

considered when making this choice.

The minimum preferable in line distance

between two bonds is 300µm, this is tool dependant and to a certain extent loop

dependant.

Bondhead Height Tolerances

Severe complications can result from electronic components (like LEMO

connectors) positioned too close to bond pads. Bonding clearance around the tool

of the 6400 is shown on this page.

The geometry of the bond head (tool, clamp, wire feed

tube, transducer etc., see below) poses restrictions on the height of electrical

components or any other objects in the vicinity of the bond pads (side

view,

3D view) made by Antoine Guipet).

Other Aspects:

Passivation

Backside of Hybrid / Pcb

Shape and size of bond pads

Pitch and layout of

bond pads

Passivation

of PCB / dies

Distance to high components

|